Materials Test Lab: Where Quality Fulfills Efficiency

Wiki Article

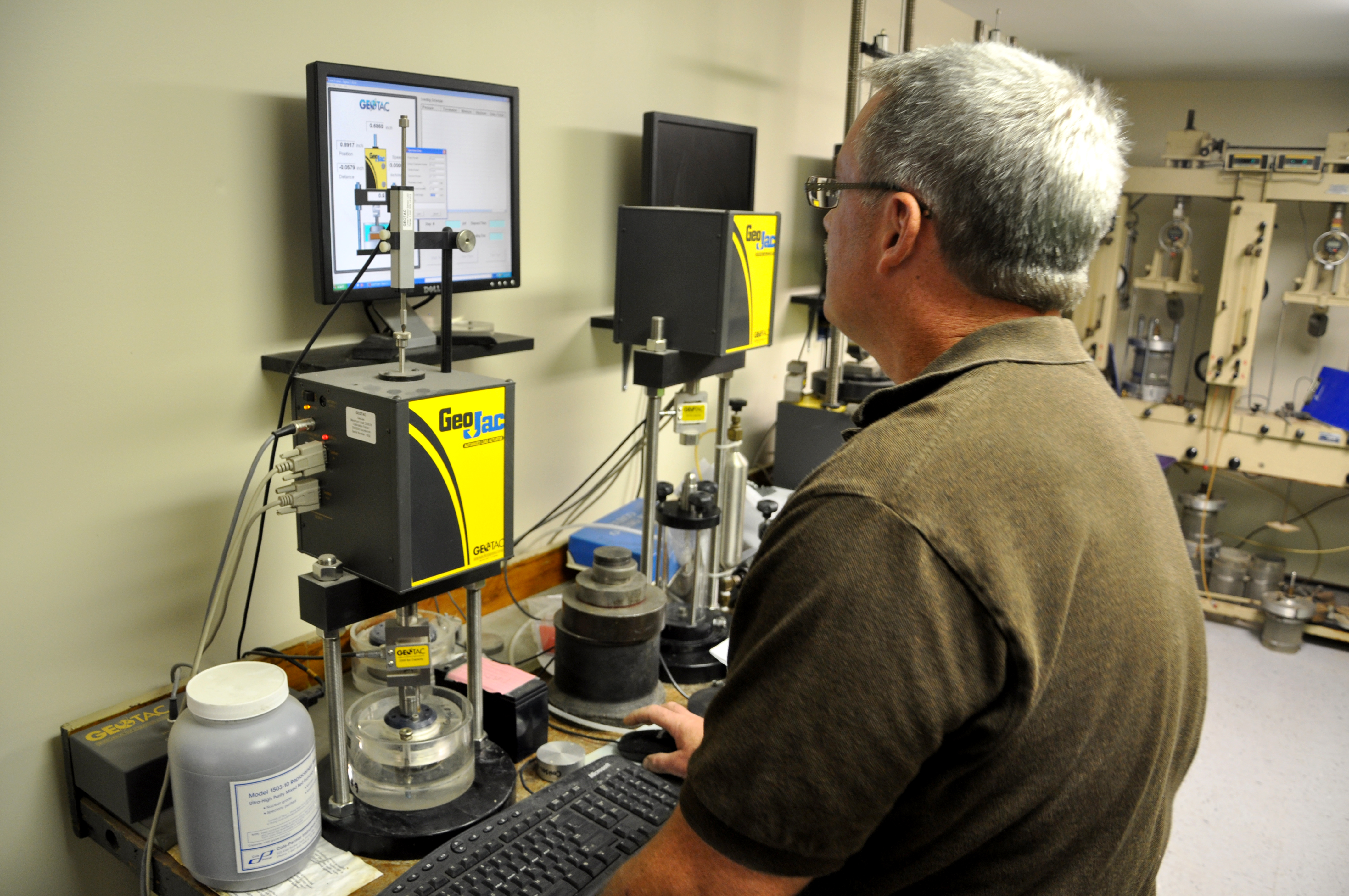

Cutting-Edge Material Screening Lab: Accelerating Innovation With Accuracy

Are you looking for an innovative material screening laboratory that can increase your innovation with accuracy? Experience the power of cutting-edge modern technology in material screening and take your innovation to brand-new elevations.Advanced Testing Tools

You ought to take a look at our advanced screening equipment, it's advanced and will certainly help you increase innovation. Our innovative research laboratory is geared up with the most recent technology to make sure accurate and accurate testing of products. With our innovative equipment, you can expect trusted results that will drive your advancement onward.One of the essential tools in our laboratory is the cutting edge global screening equipment. This machine is capable of doing a variety of tests, such as compression, flexural, and tensile examinations. With its high ability and progressed control system, you can confidently test the strength and sturdiness of your materials.

Along with the global testing maker, we likewise have actually progressed spectroscopy devices. This devices enables you to examine the chemical structure of your materials with excellent precision. By comprehending the structure of your materials, you can make educated decisions regarding their performance and suitability for your specific applications.

Additionally, our lab is outfitted with sophisticated microscopy tools. This enables you to analyze the microstructure of your materials thoroughly. By researching the microstructure, you can obtain understandings right into the material's buildings and possible locations for improvement.

Innovative Examining Approaches

Among the methods we use is non-destructive testing, which enables us to analyze the stability of products without causing any type of damages. By utilizing sophisticated imaging technologies such as ultrasonic testing and X-ray inspection, we can take a look at the inner structure of products and recognize any problems or issues. This strategy not only conserves time and sources but also makes sure that the product remains intact for additional screening or usage.

Our lab is committed to pushing the borders of product screening by utilizing these ingenious techniques. With higher accuracy and efficiency, we can offer our clients with dependable data and understandings that drive technology and enhance product development processes. Trust fund us to supply exact and reputable material screening results that will certainly push your projects to brand-new elevations.

Precision Dimensions and Analysis

Among the techniques we're making use of is non-destructive testing, which permits us to examine materials without triggering any damage. With accuracy measurements and evaluation, we can look into the composition and buildings of different products, enabling us to enhance their efficiency and enhance technology. By employing sophisticated technologies, such as X-ray imaging, ultrasonic screening, and infrared thermography, we can get detailed and precise details about the interior framework and integrity of materials without modifying their physical or chemical properties.With non-destructive screening, we can recognize any flaws, imperfections, or abnormalities that may exist within a product, guaranteeing its integrity and safety. This technique enables us to identify hidden cracks, spaces, or powerlessness in a non-invasive fashion, conserving time and resources while mitigating prospective threats. By determining these issues early on, we can proactively address them, avoiding expensive failings or crashes in the future.

In enhancement to detecting flaws, precision measurements and analysis also enable us to evaluate the performance and quality of materials. We can measure important qualities such as hardness, toughness, deterioration, and flexibility resistance, giving beneficial understandings for product choice and design optimization. By understanding these residential or commercial properties, we can develop new products with boosted performance and sturdiness, pushing the boundaries of technology.

Accelerating Products Research

By employing non-destructive screening techniques, we're able to promptly examine and evaluate various products, improving the rate and performance of our materials study. These non-destructive screening methods permit us to take a look at the homes of products without triggering any damages, saving time and sources in the process. With strategies such as ultrasonic testing, radiography, and magnetic fragment assessment, we can determine the inner structure, imperfections, and problems of products accurately and promptly.The advantage of non-destructive screening is that it allows us to collect valuable data while preserving the stability of the products being studied. We can examine you could check here the quality, dependability, and efficiency of different products without compromising their performance. This is specifically essential when dealing with expensive or unusual samples, as devastating testing would cause their destruction and prospective waste.

Along with conserving time and resources, non-destructive testing likewise boosts the safety of our research study tasks. By staying clear of the need to physically damage or alter down materials, we lessen the threat of crashes or mishaps during testing. This makes sure a secure and controlled atmosphere for our scientists and technicians.

Cutting-Edge Innovation in Material Testing

Using state-of-the-art modern technology, we can promptly and properly examine you could try this out the residential properties of various materials. With our advanced equipment and strategies, you can conserve time and sources in the material screening procedure - materials test lab. Our sophisticated devices allow for precise dimensions and evaluation, giving you a comprehensive understanding of the product's toughness, resilience, and other vital attributesThink of having the ability to establish the precise composition of a product within minutes, instead than waiting days or perhaps weeks for traditional screening techniques. Our technology allows you to do just that. By making use of non-destructive testing approaches, we can take a look at the internal framework of materials without creating any damages, guaranteeing that the honesty of the samples is maintained.

Moreover, our equipment supplies real-time information, enabling you to make enlightened decisions promptly. You can evaluate the efficiency of different products and identify any type of weaknesses or areas for renovation. This speed and precision not just improve the screening procedure but also drive innovation by enabling you to repeat and refine products a lot more efficiently.

Verdict

You have actually simply discovered the globe of a cutting-edge product screening research laboratory, where development is accelerated with precision. By using sophisticated screening equipment and innovative methods, this laboratory is at the forefront of products study.One of the methods we're using is non-destructive testing, which allows us to examine products without causing any damage.By using non-destructive screening methods, we're able to rapidly assess and examine numerous products, enhancing the speed and effectiveness of our materials research. These non-destructive screening techniques allow us to analyze the buildings of products without causing any kind of damages, saving time and sources in the procedure.You have actually just discovered the pop over to this site globe of an advanced product testing lab, where development is increased with accuracy. By making use of innovative testing tools and ingenious techniques, this lab is at the forefront of materials study.

Report this wiki page